Features

All Welded Steel Table

The table is made from 3/8 inch thick steel and welded into a single piece. We then precision machine the top of the table to be parallel with the grinding head track shafts to within .002 inches.

This means that the grinding wheel will travel parallel to the reel mounting surface to within .002 inches.

This is the foundation for the grinding concept we call Total Parallel Grinding™

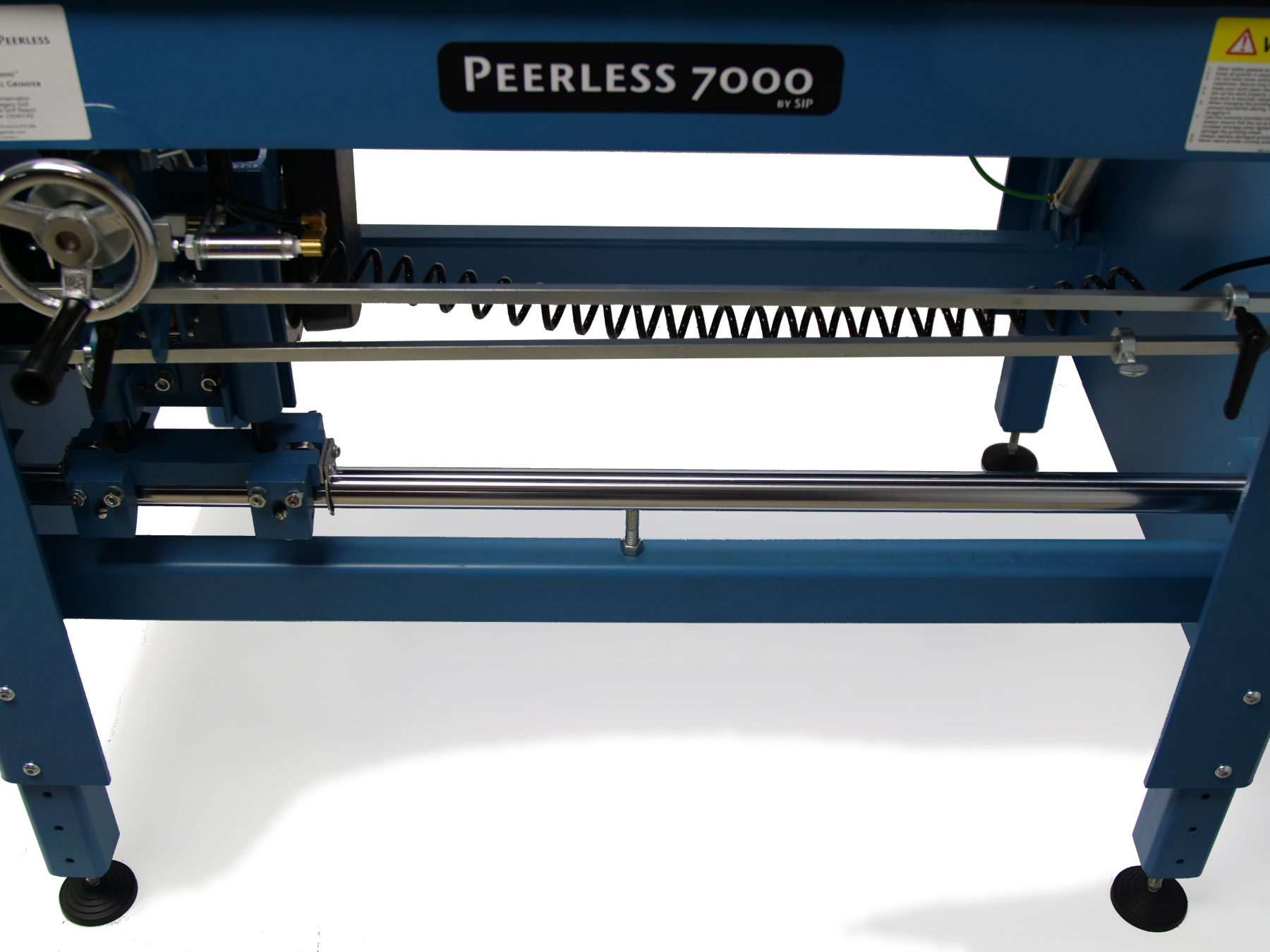

Chromed Track Shafts

The track shafts are induction hardened, turned, ground, polished and hard chrome plated for maximum precision and durability. Then they are mounted directly to the precision machined, all welded steel table.

Precision Reel Support

The reel support rails are precision machined, case hardened, blanchard ground in sets and hard nickel plated. They are also mounted directly on to the precision machined, all welded steel table.

Patented Reel Diameter Tape™

Our patented Reel Diameter Tape™ measures the actual taper of the reel to within .001 inches. Other systems try to measure the reel shape from the center shaft, which can typically vary by .015 inches or more. Not good enough when all of the mower manufacturers specify less that .010 taper for their reels.

Pneumatic Chain Clamps

The chain clamps are versatile and easy to use. Because they clamp the whole reel frame directly to the table, vibration and movement at the roller bearings is eliminated. This allows you to grind harder and faster and still get a better quality grind.

Front Loading

The polycarbonate front shield opens and closes with the flip of a switch and allows unobstructed access. Because it is both loaded (shown with the optional Simplex 800 lift table) and operated from the front, you can place it up against the wall or in a corner, taking up a lot less of your shop space.

Adjustable Legs

With over 12 inches of adjustment, the legs let you set the grinder to a comfortable operating height.